ROCKSTAR 450 Plates Suppliers, Wear Resistant ROCKSTAR 450 Plates, High Quality ROCKSTAR 450 Plates, ROCKSTAR 450 Hot Rolled Plates, Abrasion Resistant 450 Steel Plates, NICRODUR 450 Plates, ROCKSTAR 450 Plates Stockist in Mumbai, India.

ROCKSTAR 450 Sheet and Plate Exporter, BHN 450 Plates, ROCKSTAR 450 Plates Dealer, High Strength ROCKSTAR 450 Plates, ROCKSTAR 450 Cold Rolled Plates, ROCKSTAR 450 Plates Suppliers in Mumbai, ROCKSTAR 450 Plates Supplier in Mumbai, India.

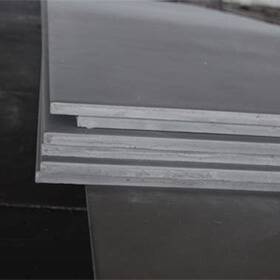

ROCKSTAR 450 Plates is a wear resistant quench and tempered steel plate grade that have an exceptional combination of resistance, formability, weldability and roughness to meet manufacturer requirements. The Rockstar plates are used in minimum and manufacture market.

All Triton Alloys customers contain unique access to our technical maintain and our information service center. In addition, we also suggest services in processing, design. They have good formability of Rockstar 450 plates among minimal consequence on hardness. We deliver a range of product to dissimilar industries. Our products are obtainable in customizable option like size, thickness and finishing to get together customer centric demands.

We have maintained a huge customer base with our amazing services and exceptional product quality.

It is simple to bend, cut, machine and weld. In all thickness 450 plates is joint with an excellent surface finish and secure thickness tolerances, as long as you’re the final application with an elevated quality look and accurate devise fitting. The hardness is mostly controlled by the carbon satisfied and by using accurate alloy compositions distribute in hardness and other properties can be reserved to a minimum.

BRAND OF ROCKSTAR 450 Plates

|

Brand

|

Manufacture/Co

|

HARDNESS RANGE

|

C.E.V. Typical Values

|

|

Values for ROCKSTAR 450

|

Thk: 10 – 20

|

||

|

QUARD 400

|

DUFERCO

|

370-430

|

0.42

|

|

JFE EVERHARD 360LE

|

JFE STEEL CORPN.

|

360-430

|

0.38

|

|

SUMIHARD K400

|

SUMITOMO METALS

|

400-440

|

0.46

|

|

ABRAZO 400

|

TATA UK LTD.

|

360-430

|

0.43

|

|

DILLIDUR 400V

|

DILLINGER HUTTE

|

370-430

|

0.43

|

|

XAR 400

|

THYSSEN KRUPP

|

370-430

|

0.43

|

|

BRINAR 400

|

ILSENBURGER GROBBLECH

|

360-430

|

0.48

|

|

FORA 400

|

INDUSTEEL

|

360-430

|

0.48

|

|

HARDPLAST 380

|

ISD HUTA

|

360-430

|

0.56

|

|

NICRODUR 400

|

ACRONI

|

360-430

|

0.56

|

|

CREUSABRO 4800

|

INDUSTEEL

|

360-430

|

0.48

|

|

WELHARD 400

|

NSC/JAPAN

|

400-440

|

0.46

|

|

BIS Plate 320

|

Bisalloy Steels Pty Ltd

|

320-360

|

0.4

|

|

BIS Plate 400

|

Bisalloy Steels Pty Ltd

|

370-430

|

0.4

|

|

BIS Plate 450

|

Bisalloy Steels Pty Ltd

|

425-475

|

0.48

|

|

Rockstar 400

|

Essar Steel India Ltd.

|

370-430

|

0.45

|

|

Rockstar 450

|

Essar Steel India Ltd.

|

425-475

|

0.52

|

|

Rockstar 500

|

Essar Steel India Ltd.

|

450-540

|

0.6

|

|

Abrex 400

|

NSSMC

|

360-440

|

0.4

|

|

Abrex 450

|

NSSMC

|

410-490

|

0.5

|

|

Abrex 500

|

NSSMC

|

450-550

|

0.55

|

|

Abrex 600

|

NSSMC

|

550-650

|

0.73

|

Corrosion Resistant: Corrosion resistant plates for sulfuric acid dew, has be at length used in flue gas treat gear such as air pre heaters, smokestacks and duct as a countermeasure for low-temperature oxidization cause by sulfur oxides. The steel also shows exceptional corrosion conflict to the corrosion problem at waste incinerate facilities, where hydrochloric acid dew corrosion consequential from lower-temperature waste gas, is anticipated. It is high-class, economical steel made of the steel material having such high oxidization resistance and produced beneath the same quality control as that for influence station.

Corrosion Resistance Steel Plate has power, workability & Weldability that are similar to ordinary steel. Corrosion Resistance Steel Plate is more inexpensive than stainless steel.

Heat Treatment: Rockstar 450 plates has obtained its mechanical properties by quench and when necessary by subsequent tempering. The properties of as provide condition cannot be retained after exposure to experience to service or preheating temperatures in the overload of 225ᵒC. Rockstar 450is not intended for extra heat treatment.

Cold forming: Bend radius is needy on the direction of bending to rolling course. Bend angle is 90ᵒ.

Quality:

A system comprises the method of quality control to be followed through the manufacturing

process of Rockstar 450 plates so that audit mechanism is introduced throughout

manufacturing itself to produce a product meeting the necessities of desired codes &

specifications. At the raw material stage, the similar is checked visually for any kind of

surface defect such as cracks, seams, overlapping, pitting as well as dimensionally. A

chemical & physical test is approved out before selecting the underdone material.

Testing’s:

Destructive test, micro and macro test non destructive test, hydrostatic test, flare test,

destruction test, ultrasonic test, radiographic test, pit corrosion test and illustration

scrutiny, charpy test, chemical test/ spectro analysis Mechanical test, hardness test,

tensile test, positive material test, intergranular corrosion test.

Documentation:

Certificate origin by legalized manufacturers/ embassy, attested certificate by suppliers,

NABL test report, raw material test report, MTC report as per EN 10204 3.1 or 3.2,

specification guide, and guarantee letter. Commercial invoice, fumigation certificates,

quantity and marks and number packing list

Packaging: Packing of this ROCKSTAR 450 Plates with this equipment Wooden boxes, crates, and cases, wound paper tubes, cartons, cores on its pallets, individual pole wrapping with stretch film

Delivery process: Quenched is tempered. The plates are delivering with sheared or thermally cut edges. Untrimmed edges are able to also be delivered subsequent to an agreement. Plates can be delivered in explosion blasted and primer coated outside condition.

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | ROCKSTAR 450, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition Of ROCKSTAR 450 Plates

|

Plate |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

B |

CEV |

CET |

|

thickness mm |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

typv |

typv |

|

3-(8) |

0.19 |

0.7 |

1.6 |

0.025 |

0.01 |

0.25 |

0.25 |

0.25 |

0.004 |

0.41 |

0.30 |

|

8-20 |

0.21 |

0.7 |

1.6 |

0.025 |

0.01 |

0.50 |

0.25 |

0.25 |

0.004 |

0.47 |

0.34 |

|

(20)-40 |

0.23 |

0.7 |

1.6 |

0.025 |

0.01 |

1.00 |

0.25 |

0.25 |

0.004 |

0.57 |

0.37 |

|

(40)-50 |

0.23 |

0.7 |

1.6 |

0.025 |

0.01 |

1.40 |

0.25 |

0.60 |

0.004 |

0.59 |

0.36 |

|

(50)-80 |

0.26 |

0.7 |

1.6 |

0.025 |

0.01 |

1.40 |

1.00 |

0.60 |

0.004 |

0.72 |

0.41 |

Mechanical Properties Of ROCKSTAR 450 Plates

|

Grade |

Mechanical Property |

Charpy V Impact Test |

|||

|

HADOX 450 |

Yield |

Tensile |

Elongation |

Degree |

longitudinal |

|

Min Mpa |

Mpa |

Min % |

-40 |

J |

|

|

1200 |

1400 |

10 |

40 |

||

ROCKSTAR 450 Plates Country Origin Make

| Brand | Manufacture/Co | Country |

| QUARD 450 | DUFERCO | Belgium |

| JFE EVERHARD 360LE | JFE STEEL CORPN. | Japan |

| SUMIHARD K400 | SUMITOMO METALS | Japan |

| ABRAZO 450 | TATA UK LTD. | UK |

| DILLIDUR 400V | DILLINGER HUTTE | Germany |

| XAR 450 | THYSSEN KRUPP | Germany |

| BRINAR 450 | ILSENBURGER GROBBLECH | Germany |

| FORA 360 | INDUSTEEL | Belgium |

| FORA 450 | INDUSTEEL | Belgium |

| HARDPLAST 380 | ISD HUTA | European |

| NICRODUR 450 | ACRONI | Europe |

| CREUSABRO 4800 | INDUSTEEL | Belgium |

| WELHARD 450 | NSC/JAPAN | Japan |

| SWEBOR 450 | SWEBOR STAL | Sweden |

| BIS Plate 320 | Bisalloy Steels Pty Ltd | Austrelia |

| BIS Plate 450 | Bisalloy Steels Pty Ltd | Austrelia |

| Rockstar 450 | Essar Steel India Ltd. | India |

| Algo Tuf 400F | Essar Steel India Ltd. | India |

| Abrex 450 | NSSMC | Japan |

| Wearalloy 450 | Ford steel | USA |

| Hardwear 400F | Arcelor Mittal. | Luxembourg |

| Roc 450 | Arcelor Mittal. | Luxembourg |

| ROCKHARD 450 | JINDAL | INDIA |

People Also Searched for ROCKSTAR 450 Plates

ROCKSTAR 450 hr plates in mumbai, ROCKSTAR grade 450 plates in india, ROCKSTAR 450 plate exporters in Mumbai, ROCKSTAR grade 450 plates dealer in mumbai, ROCKSTAR 450 plate prices, ROCKSTAR 450 coils Distributor, ROCKSTAR 450 plates stockholder in mumbai, ROCKSTAR 450 plates thickness, ROCKSTAR 450 plates specifications, ROCKSTAR plate grade 450, ROCKSTAR 450 plates, ROCKSTAR 450 plate price list, ROCKSTAR gr. 450 plates in india, ROCKSTAR 450 plates properties, ROCKSTAR 450 plate traders in mumbai, ROCKSTAR 450 slitting coils properties, ROCKSTAR 450 plate hardness, ROCKSTAR 450 plates equivalent, ROCKSTAR 450 plates & coils suppliers in india, ROCKSTAR 450 sheets & plates manufacturer in india, ROCKSTAR 450 plates supplier in mumbai, ROCKSTAR 450 grade plate stockists in mumbai, ROCKSTAR 450 plates exporter in india, 450 ROCKSTAR plates manufacturers in mumbai, ROCKSTAR grade 450 plates stockholder in india, ROCKSTAR 450 plate stockists in india, ROCKSTAR 450 sheets & plates equivalent grades, ROCKSTAR 450 plates chemical composition, ROCKSTAR 450 plates pdf.

We Offers Following Processing for ROCKSTAR 450 Sheets & Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of ROCKSTAR 450 Plates

ROCKSTAR 450 Plates

US $900-3000 / Metric Ton( FOB Price)

Wear Resistant ROCKSTAR 450 Plates

US $605-629 / Metric Ton( FOB Price)

ROCKSTAR 450 Abrasion Resistant Plates

US $2100-5100 / Metric Ton( FOB Price)

ROCKSTAR 450 High Strength Plates

US $500-800 / Metric Ton( FOB Price)

ROCKSTAR 450 Brinell

US $560-670 / Ton( FOB Price)

ROCKSTAR 450 HR Plates

US $900-2400 / Ton( FOB Price)

Applications of ROCKSTAR 450 Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products