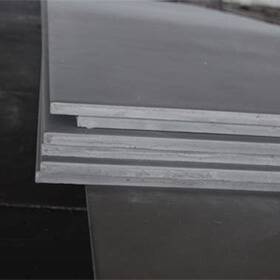

AR 400 Hot Rolled Plates, NICRODUR 400 Plates, High Quality ABREX 400 Plates, Wear Resistant ABREX 400 Plates, Abrasion Resistant 400 Steel Plates, ABREX 400 Plates Suppliers, ABREX 400 Plates Stockist in Mumbai, India.

ABREX 400 Plates Dealer, ABREX 400 Sheet and Plate Exporter, BHN 400 Plates, High Strength ABREX 400 Plates, ABREX 400 Cold Rolled Plates, ABREX 400 Plates Suppliers in Mumbai, ABREX 400 Plates Suppliers in India, ABREX 400 Plates Supplier in Mumbai, India.

Triton Alloys is the largest finned produce supplier and stockiest of ABREX 400 PLATES. It was made on the philosophy of forever recognizing the needs of its consumers and thoughtful that quality. On time delivery, price and consumer service are paramount to it’s a success. It services to reckon with in the field of developed and exporting best quality.

ABREX 400 PLATES use of opposed to ABREX steel plate noticeably reduces the weight of structural members exposed to strict conditions. Compared with other goods with ABREX steel plate reduces structural weight and bring economic merits.

It does not suffer consistent corrosion, like carbon steel when uncovered to wet environments. Unprotected steel rusts eagerly when exposing to the combination of air and moisture. The resulting iron oxide outside layer is porous and fragile. While iron oxide occupies a larger quantity than the original steel this coating expands and tends to flake and fall away revealing the underlying steel to further attack.

In comparison, stainless steels contain enough chromium to undergo passivation, form a microscopically thin inert surface film of chromium oxide by the response with the oxygen in the air and even the little amount of dissolved oxygen in the water. These passive films stop further corrosion by blocking oxygen dispersion to the steel surface and thus stop corrosion from spreading into the size of the metal.

BRAND OF AR 400 Plates

|

Brand

|

Manufacture/Co

|

HARDNESS RANGE

|

C.E.V. Typical Values

|

|

Values for AR 400

|

Thk: 10 – 20

|

||

|

QUARD 400

|

DUFERCO

|

370-430

|

0.42

|

|

JFE EVERHARD 360LE

|

JFE STEEL CORPN.

|

360-430

|

0.38

|

|

SUMIHARD K400

|

SUMITOMO METALS

|

400-440

|

0.46

|

|

ABRAZO 400

|

TATA UK LTD.

|

360-430

|

0.43

|

|

DILLIDUR 400V

|

DILLINGER HUTTE

|

370-430

|

0.43

|

|

XAR 400

|

THYSSEN KRUPP

|

370-430

|

0.43

|

|

BRINAR 400

|

ILSENBURGER GROBBLECH

|

360-430

|

0.48

|

|

FORA 400

|

INDUSTEEL

|

360-430

|

0.48

|

|

HARDPLAST 380

|

ISD HUTA

|

360-430

|

0.56

|

|

NICRODUR 400

|

ACRONI

|

360-430

|

0.56

|

|

CREUSABRO 4800

|

INDUSTEEL

|

360-430

|

0.48

|

|

WELHARD 400

|

NSC/JAPAN

|

400-440

|

0.46

|

|

BIS Plate 320

|

Bisalloy Steels Pty Ltd

|

320-360

|

0.4

|

|

BIS Plate 400

|

Bisalloy Steels Pty Ltd

|

370-430

|

0.4

|

|

BIS Plate 450

|

Bisalloy Steels Pty Ltd

|

425-475

|

0.48

|

|

Rockstar 400

|

Essar Steel India Ltd.

|

370-430

|

0.45

|

|

Rockstar 450

|

Essar Steel India Ltd.

|

425-475

|

0.52

|

|

Rockstar 500

|

Essar Steel India Ltd.

|

450-540

|

0.6

|

|

Abrex 400

|

NSSMC

|

360-440

|

0.4

|

|

Abrex 450

|

NSSMC

|

410-490

|

0.5

|

|

Abrex 500

|

NSSMC

|

450-550

|

0.55

|

|

Abrex 600

|

NSSMC

|

550-650

|

0.73

|

Localized corrosion: It is able to occur in a number of ways e.g. pitting decay and crevice corrosion. Such localized attack is mainly common in the being thereof chloride ions. Design and good manufacture techniques combined with the right alloy section can avoid such corrosion. Localized corrosion can be not easy to predict since it is dependent on many factors including.

Chloride ion concentration, rising temperature increases susceptibility, growing acidity increases susceptibility, stagnant circumstances increase weakness and the presence of oxidizing types, such as ferric and cupric ions.

Welding: ABREX 400 can be well below normal conditions by MMA, MOG and SAW without preheating, up to a combined width, provided hydrogen forbidden electrodes are used. Consumables must be dried in accord with scale D of BS 5135. Consumables should be selected on the basis of whether or not the weld metal is exposed to wear conditions.

Machining: Machining or drill is extra difficult due to hardness. For 400 ABREX BHN exercise high-grade cobalt HSS E drilling tools with for hard metal drilling tools are necessary.

Testing’s: Destructive test, positive material test, non destructive test, , charpy test, Mechanical test, hardness test, tensile test, , micro and macro test, hydrostatic test. More test are like intergranular corrosion test, chemical test/ spectro analysis, , flare test, ultrasonic test, radiographic test, pit corrosion test and illustration inspection.

Documentation:, specification guide, fumigation certificates, NABL test report, packing list like net and gross weight, Commercial invoice. Quantity and marks, number, , MTC report according to EN 10204 3.1 or 3.2 and guarantee letter. Certificate origin by legalized embassy, heat treatment charts, attested certificate by manufacturer, raw material test report, mill test report, quality assurance plan.

Packaging: ABREX 400 PLATES is sleeved keen on plastic bag independently, pieces wrap with water-proof material, bundle with nylon rope. Clear labels are the tag on the exterior of the package for easy classification of the quantity and creation. Great care is taken through operation and transportation. ABREX 400 resistant steel plate stuffing will be according to international norms in bundles strapped by strips then containers to keep away from any damage.

The plates are also packed in Wooden boxes, crates, cartons, cases, wound paper tubes, cores on its pallets, individual pole wrap with stretch film.

What is the ABREX 400 plate?

ABREX 400 Plate is made from a combination of alloying elements that provide the steel with increased hardness, strength, and toughness. ABREX 400 Wear Resistance Plates are also heat-treated to further increase their hardness & strength.

What are the common applications of the ABREX 400 plate?

ABREX 400 Wear Resistance Plates is commonly used in applications such as mining equipment, earthmoving equipment, conveyors, dump trucks, chutes, hoppers, and other equipment that is subject to high levels of wear and tear. It's also used in buildings, bridges, and infrastructure that are exposed to an abrasive environment.

What are the standard dimensions for ABREX 400 Plates?

The standard dimensions for ABREX an ABREX 400 Steel plate are thickness from 3 to 80mm and width from 1500 to 4200mm

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | ABREX 400, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition Of ABREX 400 Plates

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| 3- 6 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.41 | 0.28 |

| 3-(8) | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.30 | 0.25 | 0.25 | 0.004 | 0.33 | 0.23 |

| 8 - 20 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.37 | 0.27 |

| (20)-32 | 0.18 | 0.70 | 1.60 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.48 | 0.29 |

| (32)-45 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.31 |

| (45)-51 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.38 |

| (51)-80 | 0.27 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.65 | 0.41 |

| (80)-130 | 0.32 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.50 | 0.60 | 0.004 | 0.73 | 0.48 |

Mechanical Properties Of ABREX 400 Plates

| Grade | Mechanical Property | Charpy V Impact Test | |||

| ABREX 400 | Yield | Tensile | Elongation | Degree | longitudinal |

| Min Mpa | Mpa | Min % | -40 | J | |

| 1000 | 1250 | 10 | 45 | ||

AR 400 Plates Country Origin Make

| Brand | Manufacture/Co | Country |

| QUARD 400 | DUFERCO | Belgium |

| JFE EVERHARD 360LE | JFE STEEL CORPN. | Japan |

| SUMIHARD K400 | SUMITOMO METALS | Japan |

| ABRAZO 400 | TATA UK LTD. | UK |

| DILLIDUR 400V | DILLINGER HUTTE | Germany |

| XAR 400 | THYSSEN KRUPP | Germany |

| BRINAR 400 | ILSENBURGER GROBBLECH | Germany |

| FORA 360 | INDUSTEEL | Belgium |

| FORA 400 | INDUSTEEL | Belgium |

| HARDPLAST 380 | ISD HUTA | European |

| NICRODUR 400 | ACRONI | Europe |

| CREUSABRO 4800 | INDUSTEEL | Belgium |

| WELHARD 400 | NSC/JAPAN | Japan |

| SWEBOR 400 | SWEBOR STAL | Sweden |

| BIS Plate 320 | Bisalloy Steels Pty Ltd | Austrelia |

| BIS Plate 400 | Bisalloy Steels Pty Ltd | Austrelia |

| Rockstar 400 | Essar Steel India Ltd. | India |

| Algo Tuf 400F | Essar Steel India Ltd. | India |

| Abrex 400 | NSSMC | Japan |

| Wearalloy 400 | Ford steel | USA |

| Hardwear 400F | Arcelor Mittal. | Luxembourg |

| Roc 400 | Arcelor Mittal. | Luxembourg |

| ROCKHARD 400 | JINDAL | INDIA |

People Also Searched for ABREX 400 Plates

abrex 400 cold rolled plates supplier in mumbai, abrex 400 hr plates in mumbai, abrex 400 sheets & plates manufacturer in india, abrex 400 slitting coils properties, abrex 400 plates pdf, abrex 400 plate traders in mumbai, abrex 400 plates & coils stockholder in mumbai, abrex plate grade 400, abrex 400 plate exporters in mumbai, ar plates equivalent, abrex 400 hr plate prices, ar grade 400 plates stockholder in india, ar 400 plates specifications, abrex 400 grade plate stockists in mumbai, abrex 400 plates, 400 abrex plates manufacturers in mumbai, abrex 400 coils distributor, abrex 400 2d finish cr plates, abrex 400 plates thickness, abrex grade 400 plates in india, abrex 400 slitting coils exporter in india, ar 400 plates chemical composition, abrex 400 hr plate price list, abrex 400 sheets & plates equivalent grade, abrex gr. 400 plates in india, abrex grade 400 plates dealer in mumbai, abrex 400 hot rolled plate stockists in india, abrex 400 cr plates properties, abrex 400 plate hardness, abrex 400 plates & coils suppliers in india.

We Offers Following Processing for ABREX 400 Sheets & Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of ABREX 400 Sheets

ABREX 400 Plates

US $900-3000 / Metric Ton( FOB Price)

Wear Resistant ABREX 400 Plates

US $605-629 / Metric Ton( FOB Price)

ABREX 400 Abrasion Resistant Plates

US $2100-5100 / Metric Ton( FOB Price)

ABREX 400 High Strength Plates

US $500-800 / Metric Ton( FOB Price)

ABREX 400 Brinell

US $560-670 / Ton( FOB Price)

ABREX 400 HR Plates

US $900-2400 / Ton( FOB Price)

Applications of ABREX 400 Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products