Abrasion Resistant 600 Steel Plates, NICRODUR 600 Plates, Wear Resistant BHN 600 Plates, BHN 600 Plates Suppliers, High Quality NICRODUR 600 Plates, BHN 600 Hot Rolled Plates, BHN 600 Plates Stockist in Mumbai, India.

BHN® 600 Sheet and Plate Exporter, BHN 600 Plates Dealer, BHN 600 Plates, BHN 600 Cold Rolled Plates, High Strength BHN 600 Plates, BHN 600 Plates Supplier in Mumbai, India.

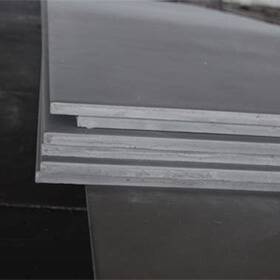

Triton Alloys which developed the first recent wear resistant plates. BHN is also known as a wear plate. This fact is particularly interesting for industries that pit gravel and sand as for illustration bucket. Surface ground BHN 600 Plates. BHN plates or steel line are used in a lot of applications where friction between two part and materials creates squalor. It is expendable items that are used to avoid excessive wear or harm to exclusive equipment.

BHN 600 is a quench and tempered martensitic wear plate for great with a typical hardness of 600 Brinell. The BHN 600 offers an exceptional combination of weldability, resistance, and roughness and is the only wear plate on the market to arrive at a hardness of 600 Brinell.

The BHN 600 represents an extensive step in the development of four elevated mills rolled quenched and tempered wear opposed to plates. Production of BHN 600 needs access to an optimal and accurate procedure control in every step of manufacturing. Indifference to the other BHN weal plates, the BHN 600 is intended only for wear applications and is not deliberate for structural use.

The BHN 600 is delivered in as quenched and tempered situation and must not be used at service temperatures more than 250ᵒC. The BHN 600 is today abounding in thicknesses and width. To optimize the weldability and machining performance two chemical compositions have been selected to cover up the present thickness range. If uncovered to sliding wear from very hard abrasives, of about 900-1000 a considerable increase in wear life can be achieved if with a wear plate of 600 Brinell.

BRAND OF BHN 600 Plates

|

Brand

|

Manufacture/Co

|

HARDNESS RANGE

|

C.E.V. Typical Values

|

|

Values for BHN 500

|

Thk: 10 – 20

|

||

|

QUARD 400

|

DUFERCO

|

370-430

|

0.42

|

|

JFE EVERHARD 360LE

|

JFE STEEL CORPN.

|

360-430

|

0.38

|

|

SUMIHARD K400

|

SUMITOMO METALS

|

400-440

|

0.46

|

|

ABRAZO 400

|

TATA UK LTD.

|

360-430

|

0.43

|

|

DILLIDUR 400V

|

DILLINGER HUTTE

|

370-430

|

0.43

|

|

XAR 400

|

THYSSEN KRUPP

|

370-430

|

0.43

|

|

BRINAR 400

|

ILSENBURGER GROBBLECH

|

360-430

|

0.48

|

|

FORA 400

|

INDUSTEEL

|

360-430

|

0.48

|

|

HARDPLAST 380

|

ISD HUTA

|

360-430

|

0.56

|

|

NICRODUR 400

|

ACRONI

|

360-430

|

0.56

|

|

CREUSABRO 4800

|

INDUSTEEL

|

360-430

|

0.48

|

|

WELHARD 400

|

NSC/JAPAN

|

400-440

|

0.46

|

|

BIS Plate 320

|

Bisalloy Steels Pty Ltd

|

320-360

|

0.4

|

|

BIS Plate 400

|

Bisalloy Steels Pty Ltd

|

370-430

|

0.4

|

|

BIS Plate 450

|

Bisalloy Steels Pty Ltd

|

425-475

|

0.48

|

|

Rockstar 400

|

Essar Steel India Ltd.

|

370-430

|

0.45

|

|

Rockstar 450

|

Essar Steel India Ltd.

|

425-475

|

0.52

|

|

Rockstar 500

|

Essar Steel India Ltd.

|

450-540

|

0.6

|

|

Abrex 400

|

NSSMC

|

360-440

|

0.4

|

|

Abrex 450

|

NSSMC

|

410-490

|

0.5

|

|

Abrex 500

|

NSSMC

|

450-550

|

0.55

|

|

Abrex 600

|

NSSMC

|

550-650

|

0.73

|

Due to the life of BHN 600, the objective is not simply to replace wear plates of less hardness, but also to substitute wear opposed to products like hard facing. Below small aspects and consequences are known on white iron chromium castings, overlay plates/ hard facing and stoneware used in applications exposed to heavy wear.

How does BHN 600 perform

Resistance to abrasive wear is not an intrinsic to abrasive wear is not an essential

material property; it depends on the application. Materials that show superior abrasion

resistance below one set of conditions might achieve poor results under dissimilar

conditions. Selecting material is complex; require wear know-how and the thought of

practical issues like application design, preservation routines, workshop necessities, and

material and fabrication costs.

In common, BHN 600 shows a somewhat lesser wear resistance compared to these types of wear-resistant materials. But below certain conditions, BHN 600 shows a wear conflict equivalent to or improved than chromium carbide-rich castings and hard opposite deposits.

When considering function, wear battle is not the only factor in terms of solidity or fraction of hard chromium carbides that determine where presentation part. Material crack inclination also plays a part. In this case, BHN 600 offers an impact roughness that exceeds the toughness of white iron castings, ceramics, and overlay and hard opposite deposits.

Testing’s: Various good quality test given high importance’s to make sure the quality of equipment like PMI/IGC test, flare test/satisfying test, chemical/mechanical test, Hydrostatic test/Radiography, pit resist test, Micro test/Macro.

Documentation: Commercial invoice, NABL test report, specification guide, , packing list like net and gross weight, quantity and marks and number, fumigation certificates, MTC report in accordance EN 10204 3.1 or 3.2 and guarantee letter.

Certificate origin, raw material test report, mill test report, , attested certificate by suppliers quality assurance plan, heat treatment charts are also offered.

Packaging: When the instance comes to the delivery of BHN 600 Plates, the dealer guarantees in supply the item by carefully packaging it uses effectual techniques like; made of wood crates/pallets boxes, cardboard box, and Shrink-wrapped.

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | BHN 600, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition Of BHN 600 Plates

|

Plate |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

B |

CEV |

CET |

|

thickness mm |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

max % |

typv |

typv |

|

8-30 |

045 |

0.7 |

1.00 |

0.015 |

0.01 |

1.2 |

2.5 |

0.8 |

0.004 |

0.73 |

0.55 |

|

(30)-50 |

0.47 |

0.7 |

1.00 |

0.015 |

0.01 |

1.2 |

2.5 |

0.8 |

0.004 |

0.84 |

0.59 |

BHN 600 Maximum Carbon equivalent CET (CEV)

| Thickness (mm) | 8.00 - 24.99 | 25.00 - 65.00 |

| Max CET(CEV) | 0.58 (0.76) | 0.61 (0.87) |

Mechanical Properties Of BHN 600 Plates

|

Grade |

Mechanical Property |

Charpy V Impact Test |

||

|

HADOX 600 |

HBW |

Elongation |

Degree |

longitudinal |

|

Min Mpa |

Min % |

-40 |

J |

|

|

570-640 |

10 |

20 |

||

BHN 600 Plates Country Origin Make

| Brand | Manufacture/Co | Country |

| QUARD 600 | DUFERCO | Belgium |

| JFE EVERHARD 360LE | JFE STEEL CORPN. | Japan |

| SUMIHARD K400 | SUMITOMO METALS | Japan |

| ABRAZO 600 | TATA UK LTD. | UK |

| DILLIDUR 400V | DILLINGER HUTTE | Germany |

| XAR 600 | THYSSEN KRUPP | Germany |

| BRINAR 600 | ILSENBURGER GROBBLECH | Germany |

| FORA 360 | INDUSTEEL | Belgium |

| FORA 600 | INDUSTEEL | Belgium |

| HARDPLAST 380 | ISD HUTA | European |

| NICRODUR 600 | ACRONI | Europe |

| CREUSABRO 4800 | INDUSTEEL | Belgium |

| WELHARD 600 | NSC/JAPAN | Japan |

| SWEBOR 600 | SWEBOR STAL | Sweden |

| BIS Plate 320 | Bisalloy Steels Pty Ltd | Austrelia |

| BIS Plate 600 | Bisalloy Steels Pty Ltd | Austrelia |

| Rockstar 600 | Essar Steel India Ltd. | India |

| Algo Tuf 400F | Essar Steel India Ltd. | India |

| Abrex 600 | NSSMC | Japan |

| Wearalloy 600 | Ford steel | USA |

| Hardwear 400F | Arcelor Mittal. | Luxembourg |

| Roc 600 | Arcelor Mittal. | Luxembourg |

| ROCKHARD 600 | JINDAL | INDIA |

People Also Searched for BHN 600 Plates

BHN 600 plates stockholder in mumbai, BHN 600 sheets & plates manufacturer in india, BHN 600 plates supplier in mumbai, BHN 600 plates chemical composition, BHN 600 plate exporters in Mumbai, BHN 600 sheets & plates equivalent grades, BHN grade 600 plates stockholder in india, BHN 600 plates properties, BHN 600 plates exporter in india, BHN gr. 600 plates in india, 600 BHN plates manufacturers in mumbai, BHN 600 plates specifications, BHN 600 plates thickness, BHN grade 600 plates in india, BHN 600 plate price list, BHN 600 plate stockists in india, BHN 600 hr plates in mumbai, BHN 600 grade plate stockists in mumbai, BHN 600 plate traders in mumbai, BHN 600 plate hardness, BHN 600 plates, BHN plate grade 600, BHN 600 plate prices, BHN 600 slitting coils properties, BHN 600 plates equivalent, BHN grade 600 plates dealer in mumbai, BHN 600 plates pdf, BHN 600 coils Distributor, BHN 600 plates & coils suppliers in india.

We Offers Following Processing for BHN 600 Sheets & Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of BHN 600 Plates

BHN 600 Plates

US $900-3000 / Metric Ton( FOB Price)

Wear Resistant BHN 600 Plates

US $605-629 / Metric Ton( FOB Price)

BHN 600 Abrasion Resistant Plates

US $2100-5100 / Metric Ton( FOB Price)

BHN 600 High Strength Plates

US $500-800 / Metric Ton( FOB Price)

BHN 600 Brinell

US $560-670 / Ton( FOB Price)

BHN 600 HR Plates

US $900-2400 / Ton( FOB Price)

Applications of BHN 600 Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products