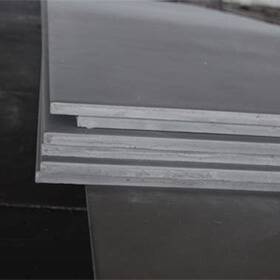

Low Alloy Steel Plates Supplier In Mumbai, Low Alloy Steel Plates Plates, Pressure Vessel Plates Stockist, EN Low Alloy Steel Plates Stockist in Mumbai, India.

Mild Steel Plates, Low Alloy Steel Hot Rolled Steel Plate, Carbon Steel Pressure Vessel Steel Plates, MS Plates, EN LOW ALLOY STEEL PLATES Suppliers, EN LOW ALLOY STEEL PLATES Suppliers in Mumbai, EN Low Alloy Steel Plates Supplier & Exporter.

Tritons Alloys is one of the largest structural steel service providers of EN LOW ALLOY STEEL PLATES in the United States. We especially tailor our centers to meet the wants of the regions they supply, and we maintain a steadfast promise to providing high-quality materials and repair promptly and economically. Our extensive list features products ranging from beams and to sheets, channels and extended and our processing capabilities include just regarding everything from cutting and drilling to blast and painting. Triton Alloys is a one-stop shop for all your structural Low alloy steel needs.

It is unwaveringly committed to client satisfaction. To that end, we struggle to maintain the highest standards of client service in the industry by providing devoted customer support. Through a single point of contact, our clients take delivery of knowledgeable, friendly service from representatives familiar with their needs. We also preserve a secure portal to help our clients remain track of documentation, counting material test reports invoices and bills of lading.

EN LOW ALLOY STEEL PLATE This low alloy steel series contain. Its carbon content on the standard is lower than 0.20%, with decent weldability and senior hardening ability due to its alloy trait. The content improves its anti-oxidization and anti-corrosion ability, and enhances its power in high-temperature condition; the steel supply conditions are generally gone from side to side annealing or normalizing and tempering processes.

Features and properties:

Chromium-Molybdenum Steel has been extensively used in the areas. The average steel in a

low-temperature environment will contain higher strength but inferior elongation and

toughness thus increase the possibility for brittle fracture.

If the steel is desirable in a low-temperature environment, having superior low-temperature

hardiness is essential. Any appropriate steel for this purpose is called low-temperature

repair steel or Nickel steel. Low Alloy Low-Temperature repair Steel is formed by adding of

Ni in the carbon steel to improve its low-temperature toughness.

Ni can make stronger ferrite matrix while lowering third transformation temperature which helps with grain formation. In addition to the normalize treatment during the production procedure of low alloy low-temperature repair steel, quenching and tempering are also parts of the mechanical properties development treatment.

Generally, there are two categories of rust preclusion method one type, for instance, paints coating, electroplate ceramic coating or addition layers of anti-corrosion material anything to protect the steel surface from the caustic environment. Another type is to use stainless steel or conditions steel, meaning adding anti-corrosion alloy essentials into the steel. Weathering steel is formed by adding small amounts and other alloy essentials into low alloy steel.

During the initial application, it will as well just like the average carbon steel; though, after certain period usually one year the rustic outside will serve as an impermeable defensive cover, preventing the further development of rust into the inner division of steel.

Testing and inspection

Rigorous test are performed under the guidance of professional experts that checks the

quality of the product. These are like Mechanical test, hardness test, tensile test, micro

and macro test ,positive material test, , chemical test/ spectro analysis, intergranular

corrosion test, burn test, flattening test, ultrasonic test, radiographic test, pitting

decay test and visual inspection.

Documentation

The documents provide are Specification guide, commercial invoice ,fumigation certificates,

packing list like net and gross weight, quantity and marks and number, NABL test report, MTC

report as per EN 10204 3.1 or 3.2 and guarantee letter.

Certificate origin by legalized manufacturers/ embassy, attested certificate by suppliers,

raw material test report, mill test report, quality assurance plan, heat treatment charts

Packaging:

At last we pack this EN LOW ALLOY STEEL PLATES with Wooden cases , boxes , cartons, and

boxes, Spiral wound paper tubes, cores on its pallets, individual pole wrap with stretch

film.

Specification

| Thickness | from 3mm up to as thick as 150mm |

|---|---|

| Size | from 2000 x 1000mm up to 4000 x 2000mm |

| Length | 3000mm-18000mm |

| Supply Condition | As Rolled, Normalized Rolling, Furnace Normalizing, Vacuum Degassing, Simulated Post-Weld Heat Treatment or as per customer requirement. |

| Impact tested | -52° C |

| Process of Manufacturing | Hot-Rolled (HR) |

People Also Searched for EN Low Alloy Steel Plates

low alloy steel plate, en low alloy steel plates, pressure vessel plates prices, plate, mild steel plate properties, en low alloy steel plate specifications, low alloy steel plate stockist in mumbai, pressure vessel steel plate stockists in india, low alloy steel plate pdf, low alloy steel plate suppliers in india, en low alloy steel plate chemical composition, mild steel plate supplier in india, low alloy steel plate hardness, ms hot rolled plates price list, low alloy steel boiler quality plates, mild steel boiler plate equivalent grade, low alloy steel properties, en low alloy steel plate in mumbai, carbon steel plate stockists in mumbai, ms plates manufacturers in mumbai india.

We Offers Following Processing for EN Low Alloy Steel Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of Alloy Steel Plates

Low Alloy Steel Plate

US $800-3000 / Metric Ton( FOB Price)

Hot Rolled Low Alloy Steel Plates

US $605-629 / Metric Ton( FOB Price)

EN Low Alloy Steel Boiler Plate

US $800-4000 / Metric Ton( FOB Price)

Pressure Vessel Steel Plates

US $500-800 / Metric Ton( FOB Price)

Export Quality Low Alloy Steel Plate

US $560-670 / Ton( FOB Price)

EN Low Alloy Steel Plates

US $500-900 / Ton( FOB Price)

Applications of Low Alloy Steel Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products