High Quality Abrasion resistant steel plate, Wear Resistant BHN Plates, Abrasion resistant steel plates Suppliers, Abrasion resistant Hot Rolled Plates, Abrasion Resistant ABREX Steel Plates, Abrasion resistant QUARD Plates Stockist in Mumbai, India.

High Strength BHN 400 Plates, Abrasion Resistant Steel Sheet and Plate Exporter, Abrasion Resistant ROCKSTAR Plates Dealer, Abrasion Resistant Cold Rolled Plates, Abrasion Resistant ROCKHARD Plates, ABRASION RESISTANT STEEL PLATE Suppliers, ABRASION RESISTANT STEEL PLATE Suppliers in Mumbai, ABRASION RESISTANT STEEL PLATE Suppliers in India, ABRASION RESISTANT STEEL PLATE Stockist in Mumbai, Abrasion Resistant Plates Supplier in Mumbai, India.

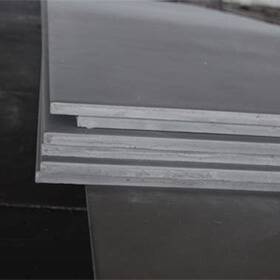

Abrasion-resistant steel plates are high carbon alloy steel sheets, providing superior resistance to impact and sliding abrasion. The high carbon content increases toughness and hardness, making them ideal for situations requiring high abrasion and impact resistance. These plates also contain a percentage of manganese, ensuring enhanced durability and toughness. Through tempering and quenching, they acquire an impact-resistant and durable surface.

The plates are forged with tempering and quenching forged steel ingots and blocks.

This process transforms the grain structure to increase toughness and formability. These AR plates are used in conditions where wear and abrasion are major concerns. Quenching is done at temperatures of around 1,500 - 1,650 degrees F and rapidly cooled with water, while tempering is performed at approximately 300-700 degrees F and cooled at normal air temperatures.

These plates offer good machinability, formability, and durability. They can withstand harsh climatic conditions and provide long-term functionality.

Fabrication Details: Triton Alloys, a leading manufacturer, supplier, and exporter of abrasion-resistant steel plates, strives to provide quality products to its esteemed patrons. The company ensures a global standard product with qualified professionals and dedicated workmanship. High-quality raw materials sourced from reputed vendors are used in the fabrication process, and the latest technology and tools are employed to design accurate dimensional products. Customer satisfaction is prioritised, and products with valuable services are offered at a nominal price. The company's wide distribution network ensures the timely delivery of products in diverse ranges, sizes, dimensions, grades, and shapes as per client requirements. The entire production process adheres to the industry's set norms and standards.

Testing and Quality Checks: Stringent quality checks and testing procedures are conducted at various production levels. These include hardness tests, mechanical tests, IGC tests, chemical analysis, flaring tests, tensile strength tests, flattening tests, pitting resistance tests, PMI tests, and macro and micro tests. These tests ensure the product's quality and are performed under strict supervision.

Test Certificates: Approved test certificates are provided to buyers to prove the product's quality and durability. These certificates include raw material test certificates, 100% radiography test reports, and third-party inspections.

Documentation: Reliable documentation is facilitated during shipping, including fumigation certificates, heat treatment charts, quality assurance plans, commercial invoices, and guarantee letters.

Packaging and Marking Details: Top-class packaging materials, such as wooden cartons, boxes, cases, and pallets, protect the products during shipping and prevent rust and damage. The products are appropriately marked with grade, trademark, size, and lot numbers.

Overall, Triton Alloys' commitment to quality & customer satisfaction makes them a trusted provider of abrasion-resistant steel plates.

What is an abrasion resistant steel plate?

Abrasion-resistant steel plate is a type of steel designed to have a higher resistance to wear and tear compared to other types of steel. It is typically made from various alloys, such as carbon steel, chromium, and manganese. It is often used in applications with high friction and impact levels.

What are the common applications of abrasion-resistant steel plates?

Wear Resistant Steel Plates are commonly used in mining, earthmoving, conveyors, dump trucks, chutes, hoppers, and other equipment subject to high wear and tear levels. It's also used in buildings, bridges, and infrastructure exposed to abrasive environments.

How is an Abrasion Resistant Steel Plate made?

Abrasion Resistant Steel Plate is made by adding specific alloying elements to standard steel. These elements, such as carbon, manganese, chromium, & molybdenum, provide the steel with increased hardness, strength, & toughness. AR Steel is then heat-treated to further increase its hardness & strength.

Abrasion Resistant Plate Properties

|

Thickness

|

Width

|

Length

|

|

4

|

2000

|

6000

|

|

5

|

2000

|

6000

|

|

6

|

2000

|

6000

|

|

6

|

2500

|

6000

|

|

8

|

2000

|

6000

|

|

8

|

2500

|

6000

|

|

10

|

2000

|

6000

|

|

12

|

2000

|

6000

|

|

15

|

2000

|

6000

|

|

16

|

2000

|

6000

|

|

20

|

2000

|

6000

|

|

25

|

2000

|

6000

|

|

32

|

2000

|

6000

|

|

40

|

2000

|

6000

|

|

50

|

2000

|

6000

|

|

60

|

1800

|

3400

|

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | BHN, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Abrasion resistant Plates Country Origin Make

| Brand | Manufacture/Co | Country |

| QUARD 400 | DUFERCO | Belgium |

| JFE EVERHARD 360LE | JFE STEEL CORPN. | Japan |

| SUMIHARD K400 | SUMITOMO METALS | Japan |

| ABRAZO 400 | TATA UK LTD. | UK |

| DILLIDUR 400V | DILLINGER HUTTE | Germany |

| XAR 400 | THYSSEN KRUPP | Germany |

| BRINAR 400 | ILSENBURGER GROBBLECH | Germany |

| FORA 360 | INDUSTEEL | Belgium |

| FORA 400 | INDUSTEEL | Belgium |

| HARDPLAST 380 | ISD HUTA | European |

| NICRODUR 400 | ACRONI | Europe |

| CREUSABRO 4800 | INDUSTEEL | Belgium |

| WELHARD 400 | NSC/JAPAN | Japan |

| SWEBOR 400 | SWEBOR STAL | Sweden |

| BIS Plate 320 | Bisalloy Steels Pty Ltd | Austrelia |

| BIS Plate 400 | Bisalloy Steels Pty Ltd | Austrelia |

| Rockstar 400 | Essar Steel India Ltd. | India |

| Algo Tuf 400F | Essar Steel India Ltd. | India |

| Abrex 400 | NSSMC | Japan |

| Wearalloy 400 | Ford steel | USA |

| Hardwear 400F | Arcelor Mittal. | Luxembourg |

| Roc 400 | Arcelor Mittal. | Luxembourg |

| ROCKHARD 400 | JINDAL | INDIA |

People Also Searched for Abrasion Resistant Steel Plates

Abrasion Resistant Steel plates stockholder in mumbai, Abrasion Resistant Steel hr plates in mumbai, Abrasion Resistant Steel sheets & plates manufacturer in india, Abrasion Resistant Steel plate exporters in Mumbai, Abrasion Resistant Steel sheets & plates equivalent grades, Abrasion Resistant Steel plates & coils suppliers in india, Abrasion Resistant Steel plates pdf, Abrasion Resistant Steel plates thickness, Abrasion Resistant Steel plates equivalent, Abrasion Resistant Steel plate hardness, Abrasion Resistant Steel plate traders in mumbai, Abrasion Resistant Steel plate price list, Abrasion Resistant Steel plates chemical composition, Abrasion Resistant Steel pla properties, Abrasion Resistant Steel plates specifications, BHN grade 500 plates dealer in mumbai, Abrasion Resistant Steel plates, Abrasion Resistant Steel plates in india, Abrasion Resistant Steel plate prices, Abrasion Resistant Steel plate stockists in india, Abrasion Resistant Steel plates exporter in india, BHN Abrasion Resistant plates stockholder in india, Abrasion Resistant Steel plates properties, Abrasion Resistant grade 450 plates in india, Abrasion Resistant steel plates manufacturers in mumbai, Abrasion Resistant plate grade 400, Abrasion Resistant Steel plates supplier in mumbai, Abrasion Resistant Steel grade plate stockists in mumbai.

We Offers Following Processing for Abrasion Resistant Sheets & Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of Abrasion Resistant Plates

Abrasion Resistant Plates

US $900-3000 / Metric Ton( FOB Price)

Wear Resistant BHN Plates

US $605-629 / Metric Ton( FOB Price)

Abrex Abrasion Resistant Plates

US $2100-5100 / Metric Ton( FOB Price)

ROCKHARD High Strength Plates

US $500-800 / Metric Ton( FOB Price)

Abrasion Resistant Brinell

US $560-670 / Ton( FOB Price)

Abrasion Resistant HR Plates

US $900-2400 / Ton( FOB Price)

Applications of Abrasion Resistant Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products