Welcome to Triton Alloys Inc., your trusted destination for superior-quality alloy steel plates. Situated in the vibrant city of Mumbai, India, we take immense pride in being recognized as a leading manufacturer and supplier of alloy steel plates catering to diverse industrial needs. With years of experience and a commitment to excellence, we have established ourselves as a reliable business partner worldwide.

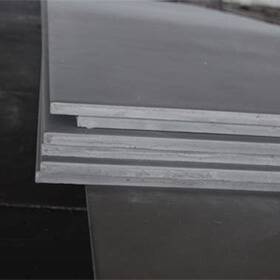

Alloy Steel Plates

Due to their remarkable strength, durability, and resistance to corrosion and abrasion, alloy steel plates are the backbone of numerous industries. These plates play a crucial role in applications ranging from structural components in construction to machinery parts in manufacturing processes. At Triton Alloys Inc., we understand the significance of these materials in various sectors, and thus, we strive to deliver top-notch products that meet the highest quality standards.

Our alloy steel plates are crafted using premium-grade raw materials from reputable suppliers. We meticulously select alloys known for their exceptional mechanical properties, such as high tensile strength, toughness, and resistance to fatigue and wear. Through stringent quality control measures and advanced manufacturing techniques, we ensure that each plate meets our stringent quality criteria before reaching our customers.

The composition of our alloy steel plates is carefully tailored to achieve optimal performance in specific applications. These plates typically blend elements such as carbon, manganese, silicon, sulfur, phosphorus, chromium, molybdenum, nickel, and others in varying proportions. This precise alloy composition enhances the overall properties of the plates, including hardness, ductility, and weldability, making them ideal for a wide range of industrial uses.

Our alloy steel plates conform to internationally recognized standards and specifications established by organizations such as ASTM, ASME, AISI, DIN, BS, and more. Each grade is assigned a specific number that signifies its chemical composition, mechanical properties, and suitability for particular applications. Commonly requested grades include ASTM A387, ASTM A204, and ASTM A514, each offering unique characteristics to meet diverse customer requirements.

We offer alloy steel plates in various shapes and dimensions to accommodate our customers' needs. Whether you require standard sizes, custom-cut pieces, or specialized forms such as coils or sheets, we can fulfil your requirements precisely and efficiently. Our state-of-the-art processing facilities and experienced team enable us to deliver tailor-made solutions that meet the most stringent specifications.

We understand the importance of competitive pricing without compromising quality. Our transparent Alloy Steel Plate Price policy ensures our customers receive fair and reasonable quotes for our alloy steel plates. We consider factors such as material costs, manufacturing processes, and market trends to offer competitive rates that provide excellent value for your investment. We are an alloy steel plates supplier with the best deals in Mumbai, and we have various grades such as ASTM A387 Grade 12 CL 1/2 Plate, A387 Grade 22 CL 1/2 Plate and many more.

Features of Alloy Steel Plates

- High Strength: Our alloy steel plates exhibit exceptional strength properties, allowing them to easily withstand heavy loads and harsh operating conditions.

- Corrosion Resistance: Our plates' alloy composition provides excellent resistance to corrosion, oxidation, and other forms of chemical degradation, ensuring long-term durability and reliability.

- Versatility: From structural components to machinery parts, our alloy steel plates offer versatility in application thanks to their excellent machinability, weldability, and formability.

- Reliability: Backed by rigorous quality control measures and adherence to industry standards, our alloy steel plates deliver consistent performance and reliability, meeting the stringent requirements of our customers across various sectors.

Triton Alloys Inc. stands as a beacon of excellence in alloy steel plates, serving as a trusted partner for businesses seeking superior-quality materials for their projects. With our unwavering commitment to quality, innovation, and customer satisfaction, we endeavour to exceed expectations and set new benchmarks in the industry. Contact us today to explore our comprehensive range of alloy steel plates and experience the difference of partnering with Triton Alloys Inc.

Specification

| Specification | ASTM A387 / ASME SA387 |

|---|---|

| Width | 1000mm-4500mm |

| Thickness | 5mm-150mm |

| Length | 3000mm-18000mm |

| Supply Condition | As Rolled, Normalized Rolling, Furnace Normalizing, Vacuum Degassing, Simulated Post-Weld Heat Treatment or as per customer requirement. |

| Impact tested | 52° C |

| Process of Manufacturing | Hot-Rolled (HR) |

People Also Searched for Alloy Steel Plates

alloy steel plate, asme sa387 alloy steel plate, a387 pressure vessel steel plates prices, astm a387 plate properties, a387 alloy steel plate specifications, chrome moly plate stockist in mumbai, pressure vessel steel plate stockists in india, alloy steel plates pdf, Chromium Molybdenum plate suppliers in india, alloy steel plate chemical composition, Chromium Molybdenum steel plate supplier in india, a387 low alloy steel plate hardness, alloy steel hot rolled plates price list, alloy steel boiler quality plates, alloy steel boiler plate equivalent grade, crmo alloy steel plate in mumbai, chrome moly plate stockists in mumbai, Chromium Molybdenum steel plates manufacturers in mumbai india.

We Offers Following Processing for Chromium Molybdenum Steel Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of CL.1/2 Plates

Alloy Steel Plate

US $800-3000 / Metric Ton( FOB Price)

Hot Rolled Steel Plates

US $605-629 / Metric Ton( FOB Price)

ASTM A387 Alloy Steel Boiler Plate

US $800-4000 / Metric Ton( FOB Price)

Pressure Vessel Plates

US $500-800 / Metric Ton( FOB Price)

Export Quality ASME SA387 Steel Plate

US $560-670 / Ton( FOB Price)

Chromium Molybdenum Steel Plates

US $500-900 / Ton( FOB Price)

Applications of Alloy Steel Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products