Wear Resistant ROCKSTAR 400 Plates, High Quality RROCKSTAR 400 Plates, NICRODUR 400 Plates, ROCKSTAR 400 Hot Rolled Plates, ROCKSTAR 400 Plates Suppliers, Abrasion Resistant 400 Steel Plates, ROCKSTAR 400 Plates Stockist in Mumbai, India.

ROCKSTAR 400 Sheet and Plate Exporter, BHN 400 Plates, ROCKSTAR 400 Cold Rolled Plates, ROCKSTAR 400 Plates Dealer, High Strength ROCKSTAR 400 Plates, ROCKSTAR 400 Plates Suppliers in Mumbai, ROCKSTAR 400 Plates Supplier in Mumbai, India.

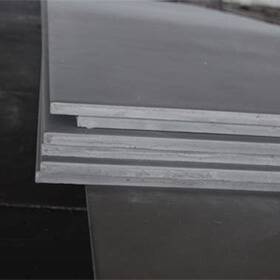

Rockstar 400 Plate is a high-strength, Abrasion Resistant Rockstar 400 Steel Plate designed for applications where durability and wear resistance are crucial. The top-quality materials, this plate is recognized for its exceptional toughness and longevity in harsh operating conditions. It belongs to the Rockstar series, renowned for delivering superior performance in challenging environments.

The Rockstar 400 Steel Plate stands out for its exceptional abrasion resistance, making it an ideal choice for industries facing severe wear and tear challenges. Its advanced composition ensures longevity and durability, minimizing downtime and maintenance costs. The plate is engineered to withstand abrasive forces, making it a reliable solution for applications requiring extended service life.

The 400 Rockstar Steel Plate boasts impressive features contributing to its overall performance. Rockstar Plate features include high-impact toughness, uniform hardness, and a fine-grained microstructure. These characteristics enhance the plate's ability to endure extreme conditions, ensuring reliable performance in diverse industrial settings. On the other hand, Rockhard 400 Plates are a high-strength, abrasion-resistant steel product designed for demanding applications in mining, construction, and manufacturing industries.

The versatility of Rockstar 400 Wear Plates makes them suitable for a broad spectrum of applications across industries such as mining, construction, agriculture, and material handling. Its ability to withstand abrasive wear and impact loading positions it as a reliable solution for components subjected to heavy-duty use.

Despite its premium quality and superior performance, the Rockstar 400 Plate is competitively priced. The Rockstar 400 Plate Price is designed to offer excellent value for money, making it an economically viable choice for businesses looking to optimize their operational efficiency without compromising quality. For those seeking a reliable Rockstar 400 Plate Supplier in India, the market offers reputable manufacturers dedicated to delivering top-notch products. With stringent quality control measures, these suppliers ensure that Rockstar 400 Plates meet the highest industry standards. As a leading 400 Rockstar Plate Manufacturer, We Triton Alloys Inc. are crucial in providing industries with the essential components for their demanding applications.

In addition to Rockstar 400 Plates, the product line includes Rockstar 500 Plates and Rockhard 400 Plates, offering a range of options to meet specific performance requirements. Each variant within the Rockstar series is designed to excel in specific applications, providing customers with tailored solutions for their unique needs. Whether facing extreme abrasion or demanding impact conditions, the Rockstar series is a reliable choice for industries seeking durable, high-performance steel plates.

BRAND OF ROCKSTAR 400 Plates

|

Brand

|

Manufacture/Co

|

HARDNESS RANGE

|

C.E.V. Typical Values

|

|

Values for BHN 400

|

Thk: 10 – 20

|

||

|

QUARD 400

|

DUFERCO

|

370-430

|

0.42

|

|

JFE EVERHARD 360LE

|

JFE STEEL CORPN.

|

360-430

|

0.38

|

|

SUMIHARD K400

|

SUMITOMO METALS

|

400-440

|

0.46

|

|

ABRAZO 400

|

TATA UK LTD.

|

360-430

|

0.43

|

|

DILLIDUR 400V

|

DILLINGER HUTTE

|

370-430

|

0.43

|

|

XAR 400

|

THYSSEN KRUPP

|

370-430

|

0.43

|

|

BRINAR 400

|

ILSENBURGER GROBBLECH

|

360-430

|

0.48

|

|

FORA 400

|

INDUSTEEL

|

360-430

|

0.48

|

|

HARDPLAST 380

|

ISD HUTA

|

360-430

|

0.56

|

|

NICRODUR 400

|

ACRONI

|

360-430

|

0.56

|

|

CREUSABRO 4800

|

INDUSTEEL

|

360-430

|

0.48

|

|

WELHARD 400

|

NSC/JAPAN

|

400-440

|

0.46

|

|

BIS Plate 320

|

Bisalloy Steels Pty Ltd

|

320-360

|

0.4

|

|

BIS Plate 400

|

Bisalloy Steels Pty Ltd

|

370-430

|

0.4

|

|

BIS Plate 450

|

Bisalloy Steels Pty Ltd

|

425-475

|

0.48

|

|

Rockstar 400

|

Essar Steel India Ltd.

|

370-430

|

0.45

|

|

Rockstar 450

|

Essar Steel India Ltd.

|

425-475

|

0.52

|

|

Rockstar 500

|

Essar Steel India Ltd.

|

450-540

|

0.6

|

|

Abrex 400

|

NSSMC

|

360-440

|

0.4

|

|

Abrex 450

|

NSSMC

|

410-490

|

0.5

|

|

Abrex 500

|

NSSMC

|

450-550

|

0.55

|

|

Abrex 600

|

NSSMC

|

550-650

|

0.73

|

The 400 Rockstar steel plate boasts impressive features contributing to its overall performance. Rockstar Plate features include high-impact toughness, uniform hardness, and a fine-grained microstructure. These characteristics enhance the plate's ability to endure extreme conditions, ensuring reliable performance in diverse industrial settings. On the other hand, Rockhard 400 plates are a high-strength, abrasion-resistant steel product designed for demanding applications in mining, construction, and manufacturing industries.

The versatility of Rockstar 400 Wear Plates makes them suitable for a broad spectrum of applications across industries such as mining, construction, agriculture, and material handling. Its ability to withstand abrasive wear and impact loading positions it as a reliable solution for components subjected to heavy-duty use.

Despite its premium quality and superior performance, the Rockstar 400 Plate is competitively priced. The Rockstar 400 plate price is designed to offer excellent value for money, making it an economically viable choice for businesses looking to optimize their operational efficiency without compromising quality.For those seeking a reliable rockstar 400 plate supplier in India, the market offers reputable manufacturers dedicated to delivering top-notch products. With stringent quality control measures, these suppliers ensure that Rockstar 400 Plates meet the highest industry standards. As a leading 400 rockstar plate manufacturer, We Triton Alloys Inc. are crucial in providing industries with the essential components for their demanding applications.

In addition to Rockstar 400 Plates, the product line includes Rockstar 500 Plates and Rockhard 400 Plates, offering a range of options to meet specific performance requirements. Each variant within the Rockstar series is designed to excel in specific applications, providing customers with tailored solutions for their unique needs. Whether facing extreme abrasion or demanding impact conditions, the Rockstar series is a reliable choice for industries seeking durable, high-performance steel plates.

What is the thickness range of Rockstar 400 plates?

Rockstar 400 plates are available in thicknesses ranging from 3 mm to 130 mm. The thickness of the plate varies according to the application requirements. The thicker the plate, the better it can resist heavy impact and abrasion.

What are the applications of Rockstar 400 plates?

Rockstar 400 plates can be used in various applications where durability and wear resistance are essential. Some common industries that use Rockstar 400 plates include mining, construction, agriculture equipment, cement plants, quarries, loading machinery, and heavy-duty machinery.

How is the quality of ROCKSTAR 400 plates assured?

The quality of ROCKSTAR 400 plates is assured through strict quality control measures. The plates undergo extensive tensile, hardness, and impact testing to meet the required standards.

Specification

| Item | Abrasion Resistant Plate |

|---|---|

| Material | ROCKSTAR 400, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition Of ROCKSTAR 400 Plates

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

| 3- 6 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.41 | 0.28 |

| 3-(8) | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.30 | 0.25 | 0.25 | 0.004 | 0.33 | 0.23 |

| 8 - 20 | 0.15 | 0.70 | 1.60 | 0.025 | 0.01 | 0.50 | 0.25 | 0.25 | 0.004 | 0.37 | 0.27 |

| (20)-32 | 0.18 | 0.70 | 1.60 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.48 | 0.29 |

| (32)-45 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.31 |

| (45)-51 | 0.22 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 0.50 | 0.60 | 0.004 | 0.57 | 0.38 |

| (51)-80 | 0.27 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.00 | 0.60 | 0.004 | 0.65 | 0.41 |

| (80)-130 | 0.32 | 0.70 | 1.60 | 0.025 | 0.01 | 1.40 | 1.50 | 0.60 | 0.004 | 0.73 | 0.48 |

Mechanical Properties Of ROCKSTAR 400 Plates

| Grade | Mechanical Property | Charpy V Impact Test | |||

| ROCKSTAR 400 | Yield | Tensile | Elongation | Degree | longitudinal |

| Min Mpa | Mpa | Min % | -40 | J | |

| 1000 | 1250 | 10 | 45 | ||

ROCKSTAR 400 Plates Country Origin Make

| Brand | Manufacture/Co | Country |

| QUARD 400 | DUFERCO | Belgium |

| JFE EVERHARD 360LE | JFE STEEL CORPN. | Japan |

| SUMIHARD K400 | SUMITOMO METALS | Japan |

| ABRAZO 400 | TATA UK LTD. | UK |

| DILLIDUR 400V | DILLINGER HUTTE | Germany |

| XAR 400 | THYSSEN KRUPP | Germany |

| BRINAR 400 | ILSENBURGER GROBBLECH | Germany |

| FORA 360 | INDUSTEEL | Belgium |

| FORA 400 | INDUSTEEL | Belgium |

| HARDPLAST 380 | ISD HUTA | European |

| NICRODUR 400 | ACRONI | Europe |

| CREUSABRO 4800 | INDUSTEEL | Belgium |

| WELHARD 400 | NSC/JAPAN | Japan |

| SWEBOR 400 | SWEBOR STAL | Sweden |

| BIS Plate 320 | Bisalloy Steels Pty Ltd | Austrelia |

| BIS Plate 400 | Bisalloy Steels Pty Ltd | Austrelia |

| Rockstar 400 | Essar Steel India Ltd. | India |

| Algo Tuf 400F | Essar Steel India Ltd. | India |

| Abrex 400 | NSSMC | Japan |

| Wearalloy 400 | Ford steel | USA |

| Hardwear 400F | Arcelor Mittal. | Luxembourg |

| Roc 400 | Arcelor Mittal. | Luxembourg |

| ROCKHARD 400 | JINDAL | INDIA |

People Also Searched for ROCKSTAR 400 Plates

ROCKSTAR plate grade 400, ROCKSTAR 400 plates & coils suppliers in india, ROCKSTAR grade 400 plates in india, ROCKSTAR 400 plates equivalent, ROCKSTAR grade 400 plates stockholder in india, ROCKSTAR 400 plate hardness, ROCKSTAR grade 400 plates dealer in mumbai, ROCKSTAR gr. 400 plates in india, ROCKSTAR 400 plates chemical composition, ROCKSTAR 400 coils Distributor, ROCKSTAR 400 hr plates in mumbai, ROCKSTAR 400 plate exporters in Mumbai, ROCKSTAR 400 grade plate stockists in mumbai, ROCKSTAR 400 plates exporter in india, ROCKSTAR 400 slitting coils properties, ROCKSTAR 400 plates supplier in mumbai, 400 ROCKSTAR plates manufacturers in mumbai, ROCKSTAR 400 plates, ROCKSTAR 400 plate stockists in india, ROCKSTAR 400 plates specifications, ROCKSTAR 400 plates properties, ROCKSTAR 400 plate prices, ROCKSTAR 400 plates thickness, ROCKSTAR 400 plates stockholder in mumbai, ROCKSTAR 400 sheets & plates equivalent grades, ROCKSTAR 400 plate traders in mumbai, ROCKSTAR 400 plates pdf, ROCKSTAR 400 plate price list, ROCKSTAR 400 sheets & plates manufacturer in india.

We Offers Following Processing for ROCKSTAR 400 Sheets & Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of ROCKSTAR 400 Plates

ROCKSTAR 400 Plates

US $900-3000 / Metric Ton( FOB Price)

Wear Resistant ROCKSTAR 400 Plates

US $605-629 / Metric Ton( FOB Price)

ROCKSTAR 400 Abrasion Resistant Plates

US $2100-5100 / Metric Ton( FOB Price)

ROCKSTAR 400 High Strength Plates

US $500-800 / Metric Ton( FOB Price)

ROCKSTAR 400 Brinell

US $560-670 / Ton( FOB Price)

ROCKSTAR 400 HR Plates

US $900-2400 / Ton( FOB Price)

Applications of ROCKSTAR 400 Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Our Products

Specialized Products