S700MC High Tensile Steel Plates, S700MC High Tensile Plates, S700MC High Tensile Structural Steel Plates, S700MC High Tensile Offshore Steel Plates, Carbon Steel S700MC Plates, EN 10149-2 S700MC Steel Plates Suppliers in Mumbai, India.

Alloy Steel S700MC Plates Exporter, S700MC High Tensile HR Plates, S700MC High Tensile Hot Rolled Steel Plates, S700MC Pressure Vessel Steel Plates Dealer, Grade S700MC Steel Plates, 1.8974 High Tensile Plates, Carbon Steel S700MC Plate Stockist in Mumbai, India.

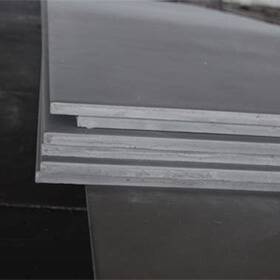

Triton Alloys Inc. is a producer, trader, and supplier of S700MC High Tensile Steel Plates. We design and supply these plates that are widely applicable in different industrial procedures and applications. Along with this, we choose S700MC to produce high tensile plates that carry high bending and welding characteristics. Our selected grade of steel that is S700MC, shows outstanding structural and mechanical properties to work in the heat treatment environment. We process the raw material for heat treatment using temper and quenching procedures. Hence, our product becomes useful in several typical applications performed in the automobile industry.

We select S700MC, which requires specifications as ASTM A514 and requires cold-forming procedures. Then, we produce each batch of products available in different widths and lengths, such as 3350 mm to 14630 mm. Along with this, our experts at Triton Alloys Inc. ensure to perform timely delivery to avoid hustle-bustle. As a result, these S700MC High Tensile Steel Plates are available in an error-free operational capacity. We perform various tests and analytical produce on to the selected material grade to ensure its capacity. We have received popularity in the global market for supplying superior quality of these S600MC High Tensile Steel Plates. Our company maintains a huge stock of these products to match the urgent orders from our esteemed clients. We choose S700MC as a raw material to produce high tensile steel plates in desired specifications and standards.

Our high tensile steel plate made from S700MC offers high yielding strength and sturdiness. Besides, we ensure to offer products that can work for a long time in extreme conditions. We ensure to supply each batch of the product by ensuring its quality and features to resist stress and strength. We provide plates without damaging surfaces by packing them in suitable material and preventing them from external elements. Our team of quality experts checks each product for its properties and features to withstand different conditions. Also, we are performing surface hardening on S700MC plates to give the product in desired features. Furthermore, we make our product carry machining procedures and activities such as bending, cutting, forging, flattening, etc.

EQUIVALENT GRADE OF S700MC Plate

| S700MC EN 10149-2 Number:1.8974 | Comparision of steel grades | |

| SEW092 | QStE 690TM | |

| NFA36-231 | E690D | |

| UNI8890 | - | |

| ASTM | A514 | |

| BS1449 | 75F70 | |

Generally speaking, it is a steel plate having high strength and low alloy structural steel covering four of the six parts with global standards. With minimum 50000ksi yield strength, it meets the requirement in chemistry and physical properties. Careful attention is always be taken on the specific variations.

These plates are mainly drawn from the hot working process. The higher mechanical efficiency is attained by annealing or heat treatment process. These plates avoid scaling in reducing environments too. These plates are resistive to pitting and crevice corrosion in environments containing a high concentration of halides and chlorides. After the heat treatment process these are subjected to solution annealing. These can be exposed to environments where the issue is chromium carbide precipitation.

These are plates are readily formable and fabricable with standard machines associated with the grade. Without any post weld heat treatment, these perform well in reducing environments.

Our quality management system controls the quality of incoming and outgoing materials by testing of raw materials. Overall quality management is thoroughly applied to our production unit in each step. Random checks are performed in each lot for mechanical and chemical properties in government approved laboratories. While the heat treatment processes the quality control system is followed for best results. Ideal fixtures and templates are used to control dimensional accuracy. The products are calibrated with global standards periodically that maintain dimensional accuracy.

The tests are as follows- chemical composition analysis, mechanical properties testing, hardness test, tensile test, positive material identifications, micro, and macro test, and hydro testing. Other material tests are the destructive/nondestructive test, intergranular corrosion test, flaring test, flattening test, ultrasonic test, radiography, pitting corrosion test and visual inspection.

S700MC plates are supplied with tests certificates as per en 10204 3.1 or 3.2. Those reports are certificate origin by legalized manufacturers, product invoice, specification guide, fumigation certificates, packing list like net and gross weight, quantity and marks and number, nabl test report, mtc report, and guarantee letter. Other certificates are attested certificate by third parties, raw material test report, mill test report, quality assurance plan, and heat treatment charts.

We supply fabricated S700MC plates in custom packing or in the form of big bundles depends on the quantity of order. Moreover, these are wrapped in plastic coatings that avoid contamination.

One can buy S700MC PLATES in various surface finishes and treatments from us!

Specification

| Item | High Tensile Steel Plate - EN 10149-2 / WNR. 1.8974 |

|---|---|

| Standard | ASTM, ASME and API |

| Size | 0.5 mm – 200 mm |

| Thickness range | 2.4mm-16mm |

| Width range | 900mm-1850mm |

| Length | 2000mm to 12000mm |

| Process of Manufacturing | Hot-Rolled (HR) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Chemical Composition Of S700MC Plate

| Grade | C max | Si max | Mn max | P max | S max | AL max | Nb max | V max | Ti max | Mo max | B max |

| S700MC | 0.12 | 0.6 | 2.1 | 0.025 | 0.015 | 0.015 | 0.09 | 0.2 | 0.22 | 0.5 | 0.005 |

Mechanical Properties Of S700MC Plate

| Grade | ReH-Minimun yield strength(Mpa) | Rm-Tensile strength(Mpa) | Nominal thickness(mm) | A-Minimum elongation Lo=5,65√So(%) | Nominal thickness(mm) | A-Minimum elongation Lo=Lo=80mm(%) |

| EN 10149-2 S700MC | 700 | 750-950 | From3 | 12 | to3 | 10 |

People Also Searched for S700MC Plate

s700mc pressure vessel steel plate in india, s700mc pressure vessel steel plate weight, s700mc high tensile plate price list, s700mc high tensile structural steel plates, s700mc high tensile steel plate mechanical properties, s700mc alloy steel plate, s700mc pressure vessel steel plate thickness, s700mc high tensile steel plate exporters in mumbai, s700mc high tensile steel plate stockholder in mumbai, s700mc structural steel hr plate, s700mc steel plates in india, s700mc high tensile plate chemical composition, s700mc en 10149-2 high tensile structural steel plates prices, s700mc high tensile steel plate stockists in mumbai, s700mc high tensile plate hardness, s700mc high tensile steel plates manufacturer in india, s700mc high tensile plate properties, s700mc high tensile steel plates in mumbai, s700mc steel plate exporter in india, s700mc hot rolled structural steel plate, s700mc hot rolled plate, s700mc high tensile steel plates dealer in mumbai, s700mc high tensile plate supplier in mumbai, s700mc high tensile plate specifications, s700mc high tensile steel plate stockholder in india, s700mc high tensile steel plate traders in mumbai, s700mc hr high tensile plate, high tensile plate grade s700mc, s700mc high tensile steel plate manufacturers in mumbai, s700mc high tensile steel plates pdf, en 10149-2 s700mc steel plate material, s700mc high tensile plate equivalent, s700mc high tensile plate stockists in india, s700mc high tensile steel plates equivalent grade, s700mc high tensile structural steel plate suppliers in india, s700mc high tensile steel plates distributor, high quality s700mc high tensile structural steel plates.

We Offers Following Processing for S700MC High Tensile Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of S700MC High Tensile Steel Plates

S700MC High Tensile Structural Steel Plate

US $800-3000 / Metric Ton( FOB Price)

S700MC Hot Rolled steel Plates

US $605-629 / Metric Ton( FOB Price)

S700MC EN 10149-2 Plates

US $800-4000 / Metric Ton( FOB Price)

S700MC Alloy Steel Plates

US $500-800 / Metric Ton( FOB Price)

S700MC (1.8974) Steel Plates

US $560-670 / Ton( FOB Price)

EN 10025-2 S700MC Plates

US $540-900 / Ton( FOB Price)

EN 10149-2 S700MC Steel Plates

US $510-900 / Ton( FOB Price)

Applications of S700MC High Tensile Steel Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Specialized Products

Our Products