Pressure Vessel 1.0982 Steel Plates, EN 10149-2 1.0982 High Tensile Structural Steel Plates, EN 10149-2 S460MC Plates, En 10149-2 1.0982 Abrasion Resistant Steel Plates, DIN 1.0982 Steel Plates, Steel 1.0982 Plates Suppliers in Mumbai, India.

En 10149-2 1.0982 Yield Steel Plates, High Strength Low EN 10149-2 Steel Plate Exporter, Offshore 1.0982 Steel Plates Dealer, Hot Rolled 1.0982 Steel Plates, DIN 1.0982 Industrial Steel Plates Stockist in Mumbai, India.

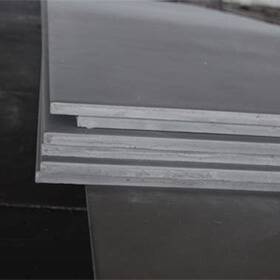

We at triton alloys are very well known for manufacturing, supplying, exporting premium quality din 1.0982 plates. We are successful in managing small and bulk orders. This grade is often referred to as corrosion resistant alloy. These are stocked in various standards and specifications; one can buy as per their application requirements.

Attractive attributes:

Din 1.0982 plates are developed for application in high-temperature corrosion resistance

applications. It is resistive to oxidation under mild cyclic environments. This grade

has resistance to sulfidation and moderate corrosion in severe carburizing environments.

These are mostly used ion thermal process. These plates can be utilized in slightly

oxidizing, cementing, nitriding and cyclic heating applications.

It also finds use in cryogenic temperatures with low magnetic properties and to down toughness. This grade is heated to subject sigma phase precipitation. These are solution annealed to restore a high degree of toughness.

Din 1.0982 plates are used for ease in fabrication. It is modified for enhanced creep resistance. In most instances, the grain size and alloying elements can meet both requirements for resistance and strength. These are readily weldable with standard shop fabrication process. All welding process can be induced on them that reduce its costs.

EQUIVALENT GRADE OF Steel 1.0982 Plate

| S460MC EN 10149-2 Number:1.0982 | Comparision of steel grades | |

| SEW092 | QStE 460TM | |

| UNE | AE440HC | |

| AFNOR | E455D | |

| ASTM | Gr.65 | |

| BS | 50F45 | |

Corrosion resistance:

These plates are developed for service in wet corrosive environments. Due to its alloying

elements, its creep properties are enhanced. It has a detrimental effect on wet corrosion

resistance. This grade is prone to igc (intergranular corrosion) even in elevated

temperatures. These are resistive to pitting and crevice corrosion in environments

containing chlorides and halides. It performs well in chemical reducing environments such as

chlorides, sulfides, alkalis, phosphoric acids, and other harsh chemicals. It is resistive

to grain boundary precipitation or sensitization. It is ideal to utilize in environments

where the issue is stress corrosion cracking.

Fabrication data:

Din 1.0982 plates are hot and cold drawn using the trending machines. We use only tested

crude materials for processing of plates. These are heated uniformly on all cross section to

develop refine grain structure. After the hot forming process, it is finally annealed and

followed rapidly by water quenching or air. The nature of grade is ductile and formability.

The cold working process is preferred to get high tensile strength and fracture toughness.

It makes its structure magnetic in nature while retaining mechanical properties. This alloy

is subjected to carbide precipitation. This alloy has great fabricability, formability, and

machinability. Hence, it is readily machinable with standard methods. After forming process,

plates processed for finishing sections to refine the surface and dimensions.

Quality management: Quality is an integral part of our firm, ranging from strategic aim to include quality testing in each operation. It makes possible, to sum up the value added to every step of productions. This demonstrates that product from triton alloys supplied is under the global standards that meet exact requirements demanded by customers. The tests performed on our products are intergranular corrosion test, flaring test, flattening test, ultrasonic test, hardness test, tensile test, and positive material test. Some other tests are mechanical test, micro and macro test, chemical test, destructive test, nondestructive test, radiographic test, pitting corrosion test and visual inspection.

In order to provide quality proof of our products, we attach certain reports with products. Those are attested certificate by suppliers, raw material test report, mill test report, quality assurance plan, heat treatment charts, nabl test report, and mtc report. Other reports are commercial invoice, specification guide, fumigation certificates, packing lists like net and gross weight, quantity and marks and number, certificate origin by legalized third-party agencies, and guarantee letter. Din 1.0982 plates are delivered in form of big bundles and customized packing.

Now you can buy these plates from us online also at a competitive price!

Specification

| Item | Structural Steel Plate - EN 10149-2 / WNR. 1.0982 |

|---|---|

| QUALITY | S460MC |

| ROLLING STATE | AR- As rolled |

| Standard | ASTM, ASME and API |

| Size | 0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTH |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Grade | EN 10149-2 S460MC DIN 1.0982 |

| DIMENSIONS | T: 1.8 – 16 mm, W: Up to 1860 mm, L: Up to 16000 mm |

| Surface and edge condition | 460MC is available with non-pickled or pickled surface with mill or cut edge. |

| Applications | Cold pressed parts for all type of vehicles, industrial tanks, containers and agricultural equipment. |

| Thickness range | S460MC |

| Width range | 750 – 2070mm (grade specific) |

| Surface treatment | Hot rolled dry, pickled & oiled |

Chemical Composition Of Pressure Vessel 1.0982 Steel Plate

| Grade | C max | Si max | Mn max | P max | S max | AL max | Nb max | V max | Ti max |

| S460MC | 0.12 | 0.50 | 1.6 | 0.025 | 0.015 | 0.015 | 0.09 | 0.2 | 0.15 |

Mechanical Properties Of High Strength Low 1.0982 Plate

| Nominal thickness(mm) | >- |

| ReH-Minimun yield strength(Mpa) | 460 |

| Nominal thickness(mm) | - |

| Rm-Tensile strength(Mpa) | 520-670 |

| Nominal thickness(mm) | From3 |

| A-Minimum elongation Lo=5,65√So(%) | 17 |

| Nominal thickness(mm) | to3 |

| A-Minimum elongation Lo=Lo=80mm(%) | 14 |

People Also Searched for 1.0982 Structural Steel Plate

offshore 1.0982 steel plate in india, din 1.0982 hot rolled steel plate exporter in india, yield 1.0982 steel plates price list, en 10149-2 abrasion resistant steel plates suppliers in india, din 1.0982 hr plate manufacturers in mumbai, en 10149-2 1.0982 plate pdf, din 1.0982 pressure vessel steel plates supplier in mumbai, steel grade s460mc plate, hot rolled 1.0982 plate distributor, 1.0982 steel plate prices, sailma 1.0982 plate stockholder in mumbai, india, grade s460mc en 10149-2 plate in india, 1.0982 plate stockists in mumbai, plate din 1.0982, din 1.0982 plates traders in mumbai, en 10149-2 1.0982 structural steel plate thickness, din 1.0982 plates, steel 1.0982 plate, wnr 1.0982 steel plates, 1.0982 steel plates chemical composition, en 10149-2 s460mc plates specifications, high tensile 1.0982 steel plates equivalent grades, steel din 1.0982 plates manufacturer in india, en 10149-2 1.0982 plate stockists in india, pressure vessel 1.0982 plates dealer in mumbai, high strength 1.0982 plate hardness, high strength low en 10149-2 1.0982 plate exporters in mumbai.

We Offers Following Processing for Sailma 1.0982 Plates

Cutting

Forming Drilling / Machining

Grinding

Testing

Price List of DIN 1.0982 Plates

DIN 1.0982 High strength steel plate

US $800-3000 / Metric Ton( FOB Price)

Hot Rolled DIN 1.0982 Steel Plates

US $605-629 / Metric Ton( FOB Price)

1.0982 Structural Steel Plates

US $800-4000 / Metric Ton( FOB Price)

High Tensile 1.0982 Steel Plates

US $500-800 / Metric Ton( FOB Price)

Grade S460MC Yield Steel Plates

US $560-670 / Ton( FOB Price)

1.0982 Abrasion Resistant Steel Plates

US $500-900 / Ton( FOB Price)

Applications of 1.0982 Structural Steel Plates

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms

Rail cars

Stone or iron chutes

Truck frames

Containers

Vehicles and transport equipment

Steel constructions

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

Specialized Products

Our Products